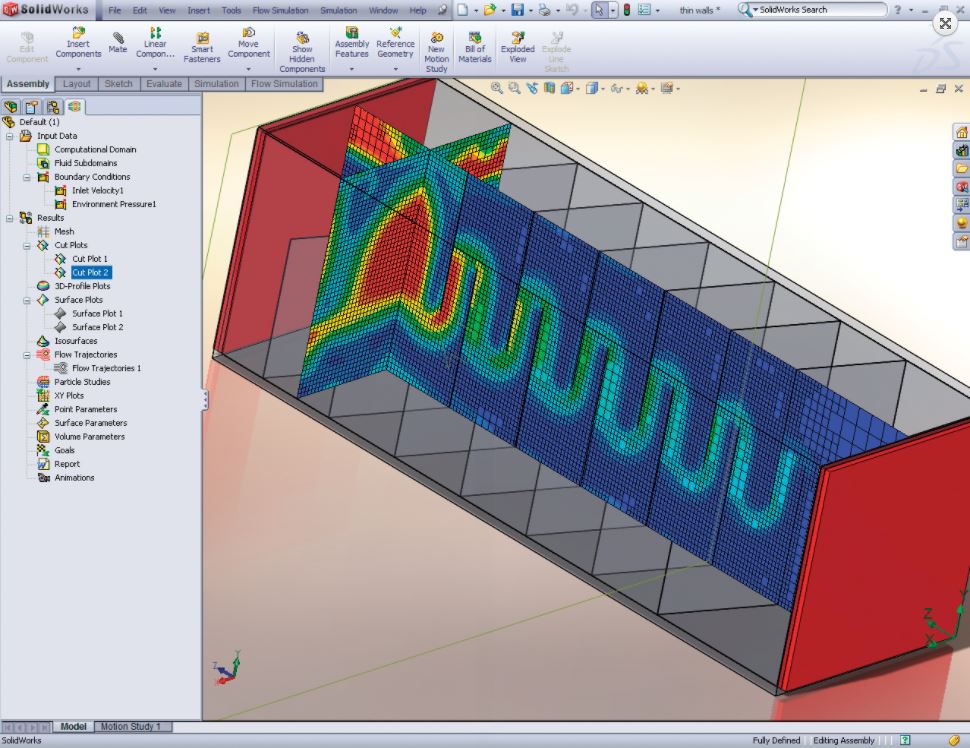

Once the lid has been created, the user must apply a flow condition to the inner face of the lid. This lid is created with an interference in the model as demonstrated in the picture below. The lid tool then creates a part in the assembly called LID1. Specifically, lids can only be created on planar (flat) surfaces (see pic below). Avoid creating lids too thick or too thin generally, the lid thickness should be the same thickness as the walls in the model around it. The lid tool allows the user to specify a thickness.

We will create 2 lids, one automatically and one manually, and we will start with the hole in the blue face (see pic below).Īutomatically create lids: using the Lid toolįortunately, SOLIDWORKS makes this very easy by providing a lid tool. We bound the inlets and outlets using lids.īelow is a model that we will be looking at in this blog. These bounded faces will then contain the info necessary to describe the flow for the inlets and outlets. Flow Simulation requires that these inlets and outlets be bounded by a face. Internal flow studies often contain geometry that have inlets and outlets.

tanks, office space, etc.) and external (not bounded by outer solid surfaces, e.g. SOLIDWORKS Flow Simulation supports two main study types, internal (flows bounded by outer solid surfaces, e.g.

0 kommentar(er)

0 kommentar(er)